Rapid prototyping has become a popular way to develop products quickly and cost-effectively. With the advances in 3D printing technology, it is now possible to produce highly detailed prototypes in a matter of days. However, the success of a rapid prototyping project depends on the materials used. Different materials have different properties, and it is important to use the right material for the job. In this article, we will explore the different types of 3D printing materials and discuss how they can be used for rapid prototyping.

Types of 3D Printing Materials

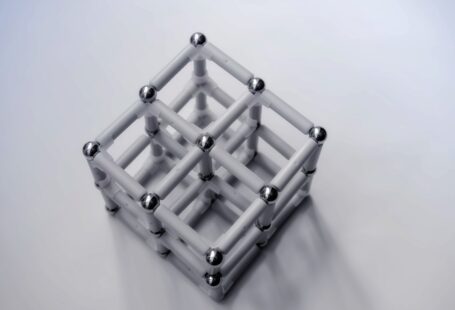

3D printing materials come in a variety of shapes and sizes, depending on the application. The most common materials used for 3D printing are thermoplastics, metal, and composite materials. Thermoplastics are the most common type of material used for 3D printing, and they come in a wide range of colors and finishes. They are flexible, lightweight, and relatively easy to work with. Metal 3D printing materials, such as aluminum and stainless steel, are ideal for producing strong, durable parts. Composite materials are a combination of two or more materials, and they offer the best of both worlds – strength, durability, and flexibility.

Advantages of 3D Printing Materials

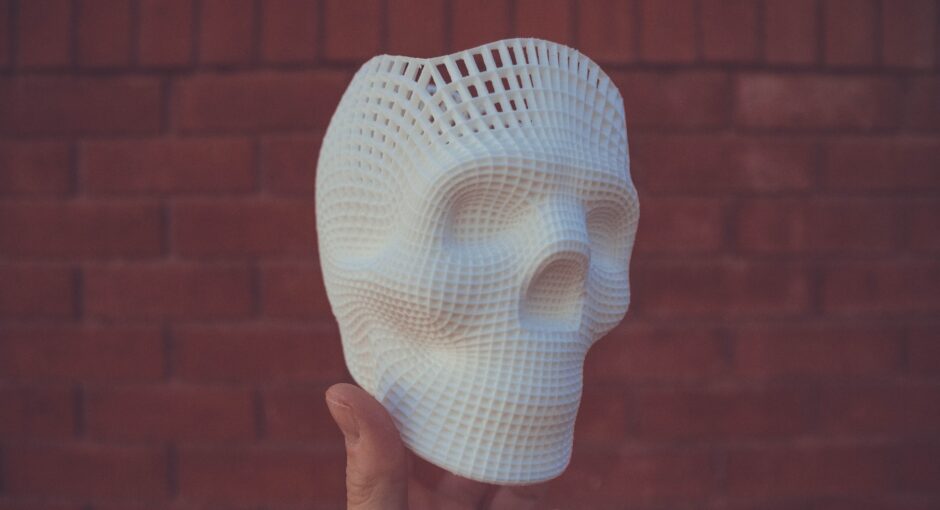

3D printing materials offer a number of advantages for rapid prototyping. They are lightweight and flexible, making them easy to transport and manipulate. They are also relatively inexpensive, making them ideal for low-volume production runs. Additionally, 3D printing materials are highly customizable, allowing for complex shapes and designs that would otherwise be difficult or impossible to create with traditional manufacturing techniques.

Applications of 3D Printing Materials

3D printing materials can be used to create a wide range of products, from industrial parts to consumer products. They are often used to create prototypes for new products, as the quick turnaround time and low cost make them an attractive option for product development. 3D printing materials can also be used for low-volume production runs, as they can produce complex parts with a high degree of accuracy. Additionally, 3D printing materials can be used to create custom parts, such as replacement parts for existing products.

Conclusion

3D printing materials have revolutionized the process of rapid prototyping, making it faster and more cost-effective than ever before. Different materials offer different advantages, depending on the application, and it is important to select the right material for the job. From creating prototypes for new products to low-volume production runs, 3D printing materials can be used to quickly and cost-effectively create a wide range of products.