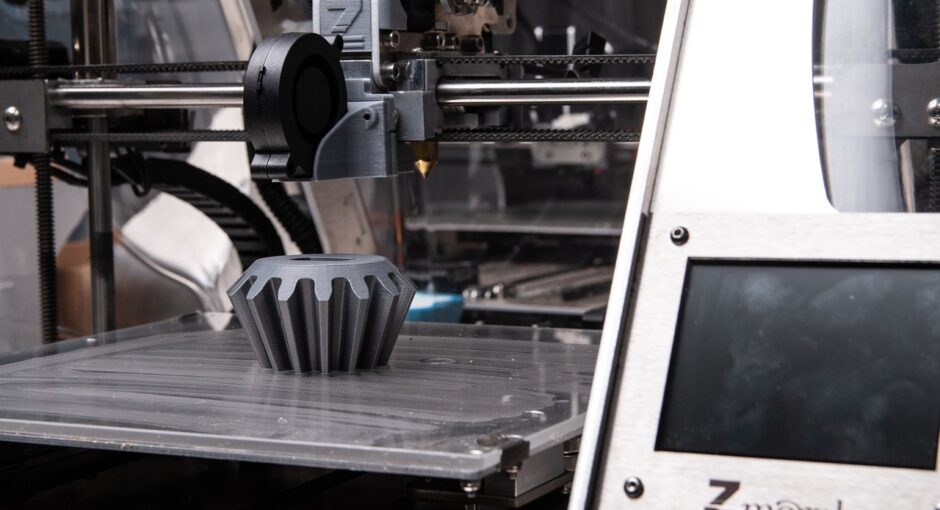

3D printing has revolutionized the manufacturing industry, allowing for the production of complex shapes and parts in a much more efficient manner than ever before. One of the materials that has become popular in 3D printing is Acrylonitrile Butadiene Styrene (ABS). This plastic material is strong, durable, and can be used to create a wide range of parts and products. In this article, we will explore the use of ABS in 3D printing, its advantages and disadvantages, and how to ensure proper use.

What is ABS?

ABS is a thermoplastic polymer that is commonly used in a variety of applications. It is a strong, durable material that is resistant to heat, chemicals, and impact. It has a relatively low melting point, which makes it ideal for 3D printing. ABS is also resistant to cracking and is a relatively inexpensive material to work with.

Advantages of ABS in 3D Printing

ABS is a great material to use in 3D printing due to its strength and durability. It is strong enough to create complex shapes and products, and it has a low melting point, making it easy to work with. ABS is also relatively inexpensive compared to other materials used in 3D printing, making it a great choice for those on a budget. Additionally, ABS is resistant to cracking and is heat and chemical resistant, making it a great choice for a wide variety of applications.

Disadvantages of ABS in 3D Printing

Although ABS is a great material for 3D printing, it does have some drawbacks. ABS has a tendency to warp when exposed to high temperatures, making it difficult to work with in certain applications. Additionally, ABS is not as strong as some other materials, making it unsuitable for certain products. Finally, ABS is more prone to cracking than some other materials, which can be a problem in certain applications.

Tips for Using ABS in 3D Printing

When using ABS in 3D printing, it is important to ensure proper use. First, it is important to make sure that the temperature is kept as low as possible. This will help to prevent warping of the ABS material. Additionally, it is important to use supports and a heated bed to ensure that the ABS sticks to the bed and does not warp. Finally, it is important to use a cooling system to ensure that the ABS cools quickly and properly.

Conclusion

ABS is a great material to use in 3D printing due to its strength, durability, and low melting point. It is relatively inexpensive compared to other materials and is resistant to cracking. However, it is important to ensure proper use of ABS in 3D printing by keeping temperatures low, using supports and a heated bed, and cooling the ABS quickly. By taking the proper precautions, ABS can be used as a great material for 3D printing.