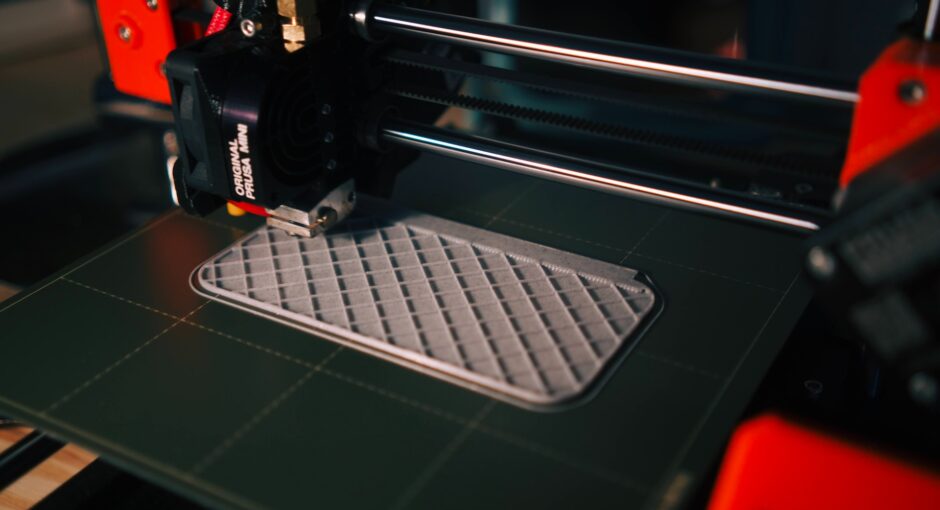

The technological advancement of 3D printing has revolutionized the way products are designed and manufactured. In the past, physical objects had to be created through carving, molding, or forming. Now, with 3D printing, objects can be designed and printed quickly and efficiently in a variety of materials. However, when printing in certain materials, it is important to understand the concept of material warping.

What is Material Warping?

Material warping is the phenomenon where the printed object is distorted from its original design due to the nature of the 3D printing material. This can be caused by a number of factors such as the type of material, the size of the object, and the print settings. When the object is printed, the material is heated and then cooled, causing it to shrink or expand in certain areas. This can cause the object to warp in one direction or multiple directions.

Types of Material Warping

There are three main types of material warping that can occur in 3D printing. The first type is known as “layer warping”. This occurs when the layers of the object are distorted due to the heat and cooling process. The second type is “part warping”. This is when the object is warped due to the properties of the material itself. The last type is “support warping”. This is when the supports are not able to keep the object in its original shape due to the weight of the object or other external forces.

Causes of Material Warping

There are several causes of material warping in 3D printing. One of the main causes is the type of material used. Different materials have different properties which can cause them to warp in different ways. Another cause is the size of the object. Larger objects tend to warp more due to the heat and cooling process. Finally, the print settings can also affect the warping. If the settings are too low, the material may not be able to cool properly, causing it to warp.

Preventing Material Warping

In order to prevent material warping in 3D printing, there are a few steps that can be taken. First, it is important to use the right material for the job. Different materials have different properties, so it is important to choose one that will not warp easily. Second, it is important to adjust the print settings accordingly. If the settings are too low, the material may not be able to cool properly, which can lead to warping. Finally, it is important to use supports when necessary. Supports can help to keep the object in its original shape and prevent warping.

Conclusion

Material warping is an important concept to understand when it comes to 3D printing. By understanding the causes and types of material warping, as well as taking the necessary steps to prevent it, designers and manufacturers can ensure that their printed objects come out as desired. With proper knowledge and preparation, 3D printing can be a successful and cost-effective way to create objects quickly and efficiently.