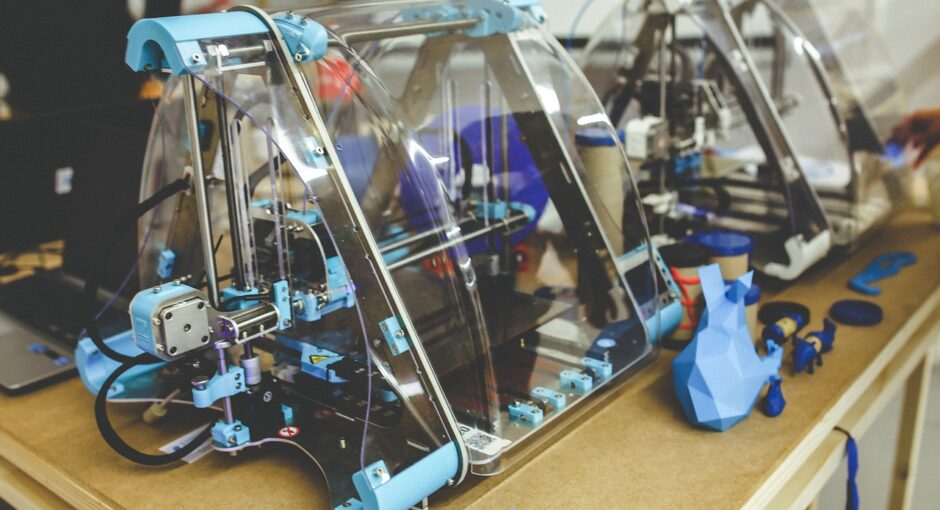

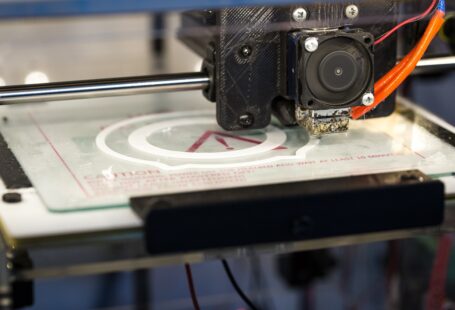

The advent of additive manufacturing has revolutionized the way products are designed and manufactured. In recent years, polycarbonate has become a popular choice as a raw material for 3D printing. This material has a number of unique properties that make it ideal for a variety of applications.

Uses of Polycarbonate in 3D Printing

Polycarbonate has a wide range of uses in 3D printing. It is strong and lightweight, making it an ideal choice for parts that need to be both durable and lightweight. It is also highly durable and resistant to impact, making it an excellent material for parts that require high levels of strength and rigidity. Furthermore, polycarbonate is chemical-resistant, so it is suitable for parts that may come into contact with corrosive materials.

Benefits of Polycarbonate in 3D Printing

Polycarbonate is a versatile material that offers a number of benefits when used in 3D printing. It is easy to work with, as it can be easily cut, drilled, and shaped into a variety of shapes and sizes. Additionally, it is easy to print on, as it has a smooth surface that offers excellent adhesion to a variety of inks and coatings. Finally, polycarbonate is a cost-effective material, as it is relatively inexpensive when compared to other materials used in 3D printing.

Types of Polycarbonate Used in 3D Printing

There are several types of polycarbonate available for use in 3D printing. The most common type is called ABS (Acrylonitrile Butadiene Styrene), which is an impact-resistant plastic that is easy to print on. Other types of polycarbonate include PC (Polycarbonate), which is strong and durable, and PETG (Polyethylene Terephthalate Glycol), which is a flexible and lightweight plastic.

Applications of Polycarbonate in 3D Printing

Polycarbonate is an ideal material for a variety of 3D printing applications. It is often used to create functional parts, such as housings for electronics or tools. Additionally, polycarbonate can be used to create prototype parts for testing and prototyping. Finally, it is also popular for creating decorative parts, such as figurines and jewelry.

Conclusion

Polycarbonate is a versatile and cost-effective material that is well-suited for use in 3D printing. It is strong and lightweight, making it ideal for parts that need to be both durable and lightweight. Additionally, it is easy to work with, as it can be easily cut, drilled, and shaped into a variety of shapes and sizes. Finally, it is cost-effective, as it is relatively inexpensive when compared to other materials used in 3D printing.