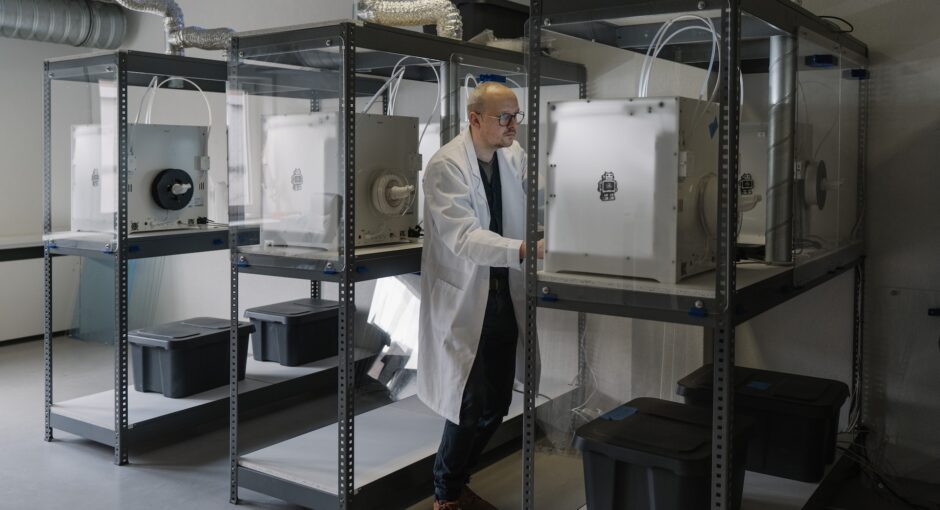

The possibilities of 3D printing have expanded exponentially in recent years. As the technology has become more advanced, its applications have grown, from paper printing to prototyping and even 3D printing of end-use products. This has been made possible largely by the advent of more advanced 3D printing materials. From polymers to metal, a wide range of materials can now be used for 3D printing, allowing engineers and designers to produce a range of objects with precise detail and accuracy.

What is 3D Printing?

3D printing is a type of additive manufacturing technology that creates three-dimensional objects from digital models. It works by depositing layers of material, typically plastic, metal, or powder, successively until the object is complete. 3D printing is used for a variety of applications, from rapid prototyping of parts to creating end-use products.

Types of Materials Used in 3D Printing

The materials used for 3D printing vary widely. The most common materials used for 3D printing are thermoplastics, which can be extruded or melted to form objects. Thermoplastics are divided into two main categories: polymers and polyamides. Polymers, such as ABS and PLA, are the most commonly used materials for 3D printing and are often used for prototyping and short-run production. Polyamides, such as nylon and polycarbonate, are more durable and heat-resistant, making them ideal for end-use parts.

Other materials used in 3D printing include metals, ceramics, and composites. Metals such as stainless steel and titanium are often used for high-strength parts, while ceramics such as aluminum oxide and zirconia are used for thermal and electrical insulation. Composite materials, such as carbon fiber and glass-filled polymers, are perfect for parts requiring strength and weight reduction.

Advantages of 3D Printing Materials

The materials used for 3D printing have a number of advantages. For one, they are highly customizable, allowing for the creation of complex geometries and designs. Additionally, 3D printing materials can be selected to meet specific requirements, such as strength, flexibility, and temperature resistance. This makes them ideal for creating parts with intricate designs and tight tolerances.

3D printing materials also offer benefits in terms of cost and time savings. By using 3D printing materials, engineers and designers can reduce the number of steps required to create a part, allowing them to quickly create prototypes and end-use products. Additionally, 3D printing materials are generally less expensive than traditional manufacturing methods, making them a cost-effective option for producing parts in small quantities.

Conclusion

3D printing materials have revolutionized the way we design and manufacture objects. From polymers to metals, there is a wide range of materials that can be used for 3D printing, allowing engineers and designers to produce objects with precise detail and accuracy. Additionally, 3D printing materials offer a number of advantages, such as cost and time savings, as well as the ability to create complex geometries and designs. As the technology continues to advance, 3D printing materials will only become more versatile and efficient.