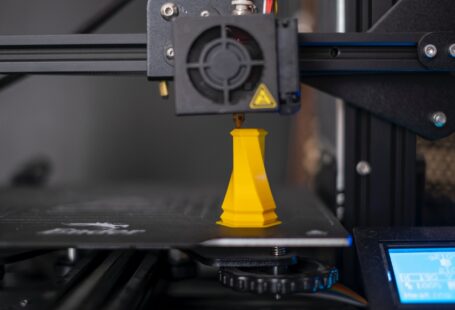

The world of 3D printing has revolutionized the manufacturing industry, allowing for the production of complex objects with unprecedented speed and accuracy. But while the technology has matured, the materials used to create 3D printed objects have remained largely the same. The majority of 3D printing materials are plastic-based, limiting the range of objects that can be produced. Now, a new wave of 3D printing materials is emerging, offering a more sustainable and versatile alternative to plastics.

Bio-Based Materials

Bio-based materials are a rapidly growing category of 3D printing materials that use plant-based polymers instead of petroleum-based plastics. These materials are not only more sustainable, but they are also stronger and more durable than traditional plastic-based materials. Examples of bio-based 3D printing materials include PLA (polylactic acid), PHA (polyhydroxyalkanoates) and PETG (polyethylene terephthalate glycol).

Metal Alloys

Metal alloys are another type of 3D printing material that is gaining traction in the industry. Metal alloys offer superior strength and durability compared to plastic-based materials, making them ideal for applications that demand high performance. Examples of metal alloys used for 3D printing include aluminum, stainless steel, and brass.

Hybrid Materials

Hybrid materials are a new type of material that combines the properties of both plastic-based and metal-based materials. These materials offer the best of both worlds, combining the strength of metal alloys with the flexibility of plastic-based materials. Examples of hybrid materials used for 3D printing include nylon, carbon fiber, and Kevlar.

The Benefits of New 3D Printing Materials

The use of new 3D printing materials opens up a range of new possibilities for manufacturers. By using bio-based materials, manufacturers can reduce their reliance on petroleum-based plastics, resulting in a more sustainable production process. Metal alloys and hybrid materials offer enhanced strength and durability, allowing manufacturers to create larger and more complex objects that would be impossible with plastic-based materials.

The Future of 3D Printing Materials

The future of 3D printing materials lies in the development of new and innovative materials. Researchers are currently exploring a range of new materials, such as graphene, conductive inks, and bioplastics, that could revolutionize the 3D printing industry. As the technology continues to evolve, manufacturers will have access to an ever-growing range of materials that can be used to create complex and high-performance objects.

The journey beyond plastics is only just beginning. With the emergence of new 3D printing materials, manufacturers now have access to a wide range of materials that can be used to create highly complex and durable objects. As researchers continue to explore new possibilities for 3D printing materials, the industry will continue to evolve and move forward.