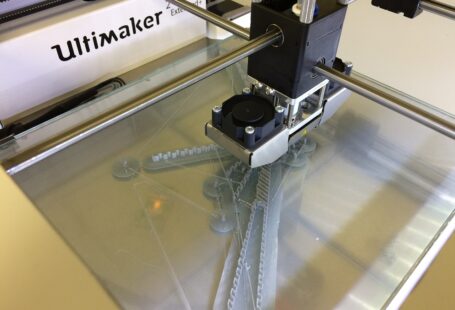

3D printing has become a popular manufacturing technique, allowing for the production of complex objects quickly and efficiently. However, to get the best results from 3D printing, it is important to prepare the specialty materials correctly. This guide will provide an overview of the different types of materials used in 3D printing, and the steps required to prepare them for printing.

Types of Materials

3D printing materials are typically divided into two categories: thermoplastics and photopolymers. Thermoplastics can be heated, melted, and cooled again without any permanent changes to their chemical structure. Some common thermoplastics used for 3D printing include ABS, PLA, and PETG. Photopolymers are light-sensitive materials that can be cured with a laser or LED light source. Common photopolymers used in 3D printing include Resin, PolyJet, and SLA.

Material Preparation

Regardless of the type of material used, 3D printing requires that the materials be prepared properly. This includes ensuring that the material is free of any impurities, such as dust or debris, that could cause problems during printing. It also involves making sure that the material is the correct size and shape for the printer. This can be achieved by using a grinding machine, a sander, or a CNC router.

Material Properties

The properties of the specialty materials used in 3D printing will have a significant impact on the quality of the final object. It is important to ensure that the material being used has the necessary properties for the application. For example, a material with a higher melting point may be required for a part that will be exposed to high temperatures. Similarly, a material with a higher strength-to-weight ratio may be needed for a part that will be subjected to heavy loads.

Material Testing

Before any material is used for 3D printing, it should be tested to ensure that it meets the required specifications. This can be done by performing a series of tests, such as thermal expansion, tensile strength, and flexural strength. This will provide an indication of how the material will perform when used for 3D printing.

Conclusion

3D printing requires the use of specialty materials that must be prepared correctly to ensure the best results. This involves ensuring that the material is free of impurities, the correct size and shape for the printer, and has the necessary properties for the application. Additionally, the material should be tested to ensure that it meets the required specifications. By following these steps, it is possible to prepare the specialty materials correctly for 3D printing.