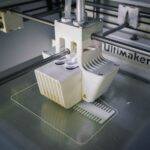

The industrial sector is a major player in global markets and many companies are striving to stay ahead of the competition by continuously optimising their processes. One of the most effective ways to increase efficiency and reduce costs is to utilise 3D printing materials. This type of technology can revolutionise the way businesses manufacture products, reduce waste, and introduce new products to the market quickly and cost effectively.

Advantages of Using 3D Printing Materials

3D printing materials offer a host of advantages to businesses looking to optimise their industrial processes. The most significant benefits include:

- Faster Production – 3D printing materials allow businesses to produce products quickly and efficiently without the need for expensive moulds, tools, and other traditional manufacturing processes.

- Reduced Wastage – With 3D printing materials, businesses can produce customised products with minimal wastage. This means that businesses can produce products that are exactly what the customer wants, reducing waste and costs associated with producing products that are not used.

- Cost Savings – As 3D printing materials reduce the need for expensive moulds and tools, businesses can save money on manufacturing costs. This can be especially beneficial for businesses that are looking to introduce new products to the market quickly.

- Flexibility – 3D printing materials allow businesses to produce customised products with relative ease. This means that businesses can quickly and easily adapt to changing customer demands and trends.

Types of 3D Printing Materials

3D printing materials come in a variety of different forms, from traditional polymer-based materials to metal alloys and ceramics. The type of material used will depend on the specific application and the desired results. Some of the most common 3D printing materials include:

- Polymer-based Materials – These materials are the most commonly used for 3D printing and are typically composed of thermoplastics, such as ABS, PETG and Nylon. They are relatively cheap and easy to use, making them popular for hobbyists and low-volume production.

- Metal Alloys – Metal alloys are more expensive than polymer-based materials, but are ideal for high-volume production and applications that require high strength and durability. Common metals used in 3D printing include aluminium, steel, and titanium.

- Ceramics – Ceramic materials are often used for medical and dental applications, as well as for creating artistic pieces. These materials are more expensive than polymer-based materials, but offer a unique finish and durability.

Conclusion

3D printing materials offer businesses a range of advantages when it comes to optimising their industrial processes. From faster production to reduced wastage and cost savings, 3D printing materials can revolutionise the way businesses manufacture products. With a variety of different materials available, businesses can tailor their 3D printing processes to suit their specific needs and objectives.