The emergence of 3D printing technology has revolutionized the manufacturing industry, changing the way products are designed and produced. With the ability to quickly and accurately create complex designs and objects, 3D printing has opened up a world of possibilities for businesses and individuals. However, with these new possibilities come new safety concerns in the form of hazardous materials that may be used in the 3D printing process. To ensure the safety of everyone involved, it is important to consider the various safety risks associated with 3D printing materials and take the necessary steps to reduce them.

Types of 3D Printing Materials

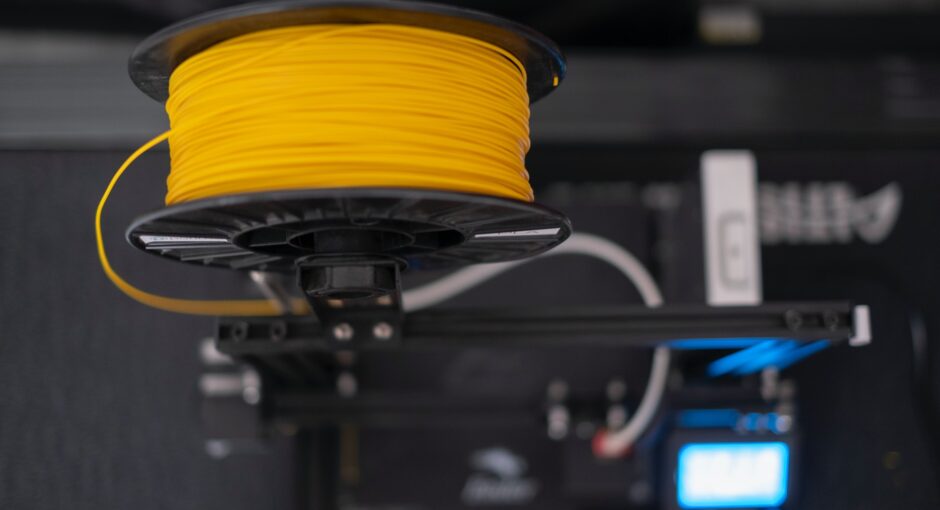

3D printing materials can be divided into two broad categories: thermoplastics and metals. Thermoplastics are the most common materials used in 3D printing, and they include materials such as PLA, ABS, and PETG. Metals used in 3D printing include stainless steel, titanium, and aluminum. Each of these materials has its own unique properties and safety considerations associated with them.

Safety Considerations for Thermoplastic Materials

Thermoplastics are the most commonly used materials in 3D printing, but they can also be the most hazardous. Many thermoplastics emit toxic fumes when heated, which can be dangerous if inhaled. Additionally, some thermoplastics are flammable, so it is important to take proper safety precautions when using them, such as proper ventilation and fire safety equipment.

Safety Considerations for Metal Materials

Metal materials used in 3D printing are generally considered to be much safer than thermoplastics, but there are still a few safety risks associated with them. Metal materials are prone to rusting if not properly cared for, and they can also become very hot during the 3D printing process. To reduce the risk of injury, it is important to wear protective clothing, such as gloves and safety glasses, when handling hot metals. Additionally, metal materials should be properly stored in a cool, dry area to prevent rusting.

Proper Handling and Storage of 3D Printing Materials

No matter what type of material is being used in 3D printing, it is important to follow proper safety protocols when handling and storing 3D printing materials. All materials should be stored in a cool, dry place away from direct sunlight, and any spilled or leaked material should be cleaned up immediately. Additionally, all 3D printing materials should be handled with care and disposed of properly after use.

Conclusion

The emergence of 3D printing technology has created numerous possibilities for businesses and individuals, but with these possibilities come new safety concerns. To ensure the safety of everyone involved, it is important to consider the various safety risks associated with 3D printing materials and take the necessary steps to reduce them. This includes properly handling and storing 3D printing materials, wearing the necessary protective clothing when handling metals, and properly disposing of materials after use. Taking these steps can help ensure the safety of everyone involved in the 3D printing process.