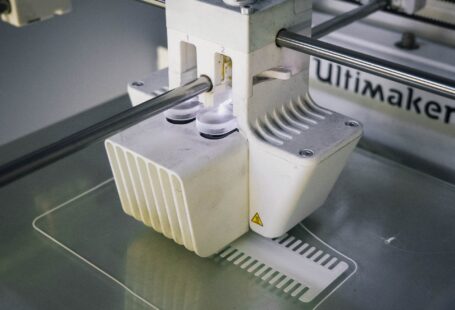

3D printing has revolutionized the way that objects are manufactured, allowing for a level of customization unlike anything seen before. As the technology has advanced, the materials used have become more and more diverse. Flexible 3D printing materials are among the most exciting of these new materials, and their uses are rapidly expanding.

What is Flexible 3D Printing?

Flexible 3D printing is a type of 3D printing that uses materials that are flexible and elastic. These materials are able to bend, stretch, and compress without breaking, which allows them to be used in a variety of applications. Flexible 3D printing materials can be used to create objects that are more durable, flexible, and lightweight than traditional 3D printing materials.

Benefits of Flexible 3D Printing Materials

Flexible 3D printing materials offer a number of benefits over traditional 3D printing materials. For example, they are able to be used in applications where traditional materials would not be suitable. Additionally, they can be used to create objects that are more durable, flexible, and lightweight than traditional materials. Furthermore, these materials can be used to create objects with complex geometries, such as those with curved surfaces or intricate details.

Types of Flexible 3D Printing Materials

There are a variety of flexible 3D printing materials available. These materials include thermoplastic elastomers (TPE), thermoplastic urethanes (TPU), polyurethanes (PU), polyether block amides (PEBA), and polyvinylidene fluoride (PVDF). Each of these materials has different properties, allowing them to be used in different applications. For example, TPE is often used to create flexible and durable objects, while PU is often used to create objects with a more flexible and lightweight feel.

Applications of Flexible 3D Printing Materials

Flexible 3D printing materials are being used in a variety of applications, from consumer products to medical devices. For example, flexible 3D printing materials are being used to create consumer products such as phone cases and shoe soles. They are also being used to create prosthetics, medical implants, and surgical instruments. In addition, flexible 3D printing materials are being used to create objects with complex geometries, such as those with curved surfaces or intricate details.

Conclusion

Flexible 3D printing materials are revolutionizing the way that objects are manufactured. These materials are able to be used in applications where traditional materials would not be suitable, and they can be used to create objects with complex geometries. They are also more durable, flexible, and lightweight than traditional 3D printing materials. As the technology continues to advance, the uses for flexible 3D printing materials will continue to expand.