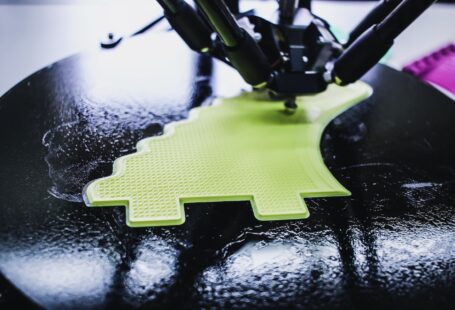

The advancement of 3D printing technology has enabled a wide range of manufacturing opportunities, from prototyping to large-scale production. However, with this technology comes a responsibility to ensure that the materials used are safe, reliable, and of high quality. Testing 3D printing materials is an essential part of the process, as it helps ensure that the final product meets the necessary standards.

Safety and Quality

3D printing materials are used to create objects in a variety of shapes and sizes. As such, it is essential that these materials meet certain safety and quality standards. Testing is an important step in the 3D printing process as it helps to ensure that the materials are safe to use and that the final product meets the necessary criteria.

Testing can include both physical and chemical tests, depending on the type of material being used. Physical tests usually involve examining the properties of the material, such as its strength, flexibility, and temperature resistance. Chemical tests, on the other hand, involve testing for potential contaminants or other substances that could potentially harm the user.

Material Compatibility

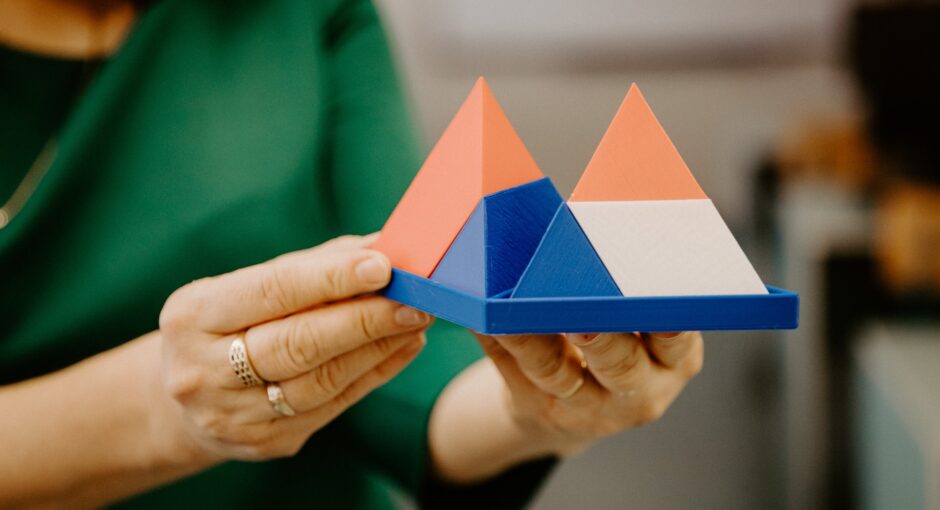

In addition to safety and quality, it is also important to consider the compatibility of the 3D printing materials. This is because certain materials may be incompatible with others, meaning that they cannot be used together. For example, certain plastics may melt when exposed to certain metals, or certain resins may not adhere to certain substrates.

Testing for material compatibility is an essential part of the 3D printing process. By testing different combinations of materials, manufacturers can ensure that they are using the right combination for their product. This helps to prevent any problems that could arise from using incompatible materials.

Cost-effectiveness

Testing 3D printing materials can also help to reduce costs. By testing the materials before manufacture, manufacturers can identify any potential issues that could lead to costly mistakes. In addition, testing can help to identify any problems that could arise during the manufacturing process, allowing manufacturers to take corrective action before the product is complete.

Conclusion

Testing 3D printing materials is an essential part of the manufacturing process. By testing the materials for safety, quality, and compatibility, manufacturers can ensure that the final product meets the necessary standards and is cost-effective. Testing also helps to identify any potential issues that could arise during the manufacturing process, allowing manufacturers to take corrective action before the product is complete.