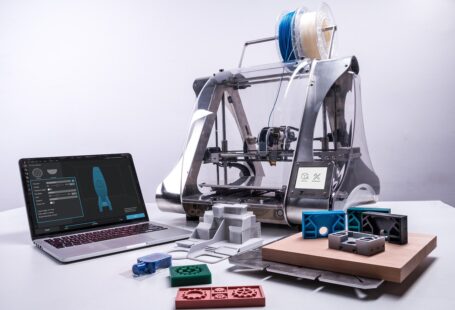

Making the right material choice is an important step in 3D printing. The material chosen can have a significant impact on the speed of the printing process. This article will discuss the various material choices and how they affect 3D printing speed.

Types of 3D Printing Materials

There are many different types of 3D printing materials available. These include plastics, metals, composites, and ceramic-based materials. Each material has its own unique properties and characteristics, which can have an effect on the speed of the printing process.

Plastics are the most commonly used materials in 3D printing. They are inexpensive, durable, and easy to work with. However, they are also slow to print and require a lot of pre-processing before they can be used.

Metals are often used for parts that require high strength and durability. They are more expensive than plastics, but they can be printed much faster. Additionally, metals require minimal pre-processing and can be used for complex shapes and designs.

Composites are a combination of two or more materials. They can be used to create parts with a wide range of properties, such as strength, flexibility, and durability. However, composites are also more expensive and require a lot of pre-processing before they can be used.

Ceramic-based materials are also used in 3D printing. They are typically used for parts that require very high precision and accuracy. Ceramic-based materials are also more expensive and require a lot of pre-processing before they can be used.

Factors That Affect 3D Printing Speed

The material chosen for 3D printing can have a significant impact on the speed of the process. There are a few factors that can affect the speed of 3D printing, including:

- Material properties: Each material has its own unique properties, and these can affect the speed and accuracy of the printing process.

- Printing speed: The speed of the 3D printer can also have an effect on the speed of the printing process. Faster printers can produce parts more quickly than slower ones.

- Layer thickness: The thickness of the layers can also affect the speed of the printing process. Thicker layers are generally faster to print than thinner layers.

- Number of parts: The number of parts being printed can also have an effect on the speed of the printing process. More parts can take longer to print than fewer parts.

Conclusion

Making the right material choice is an important step in 3D printing. The material chosen can have a significant impact on the speed of the printing process. Plastics are the most commonly used materials, but metals, composites, and ceramic-based materials can also be used. Each material has its own unique properties, and these can affect the speed of the printing process. Additionally, the speed of the 3D printer, the thickness of the layers, and the number of parts being printed can all affect the speed of 3D printing.