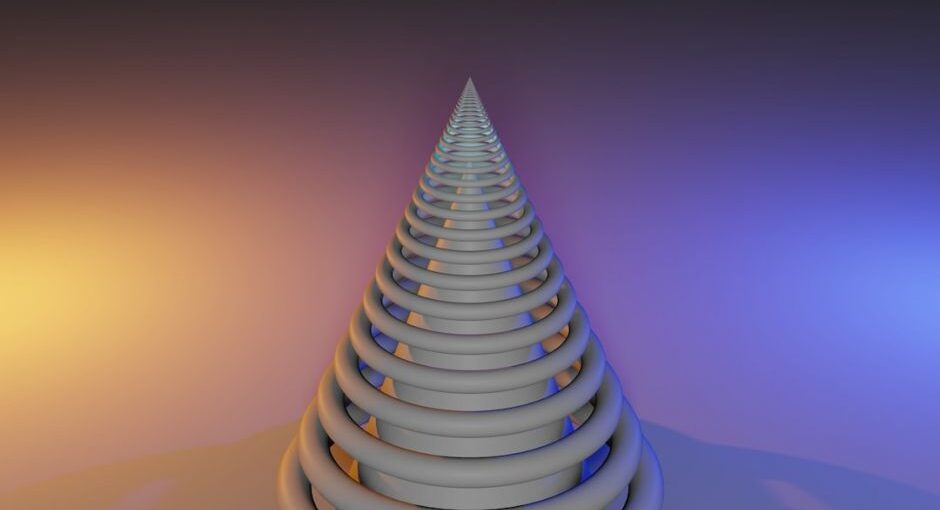

The modern world of 3D printing is continuously undergoing changes and advancements that are pushing the boundaries of what is possible in the field. One of the latest developments that are redefining 3D printing capabilities is the use of ceramics. This material has been used in traditional manufacturing processes for centuries, but its unique properties make it an ideal choice for 3D printing. In this article, we will explore how ceramics are being used to expand the possibilities of 3D printing.

Ceramics for 3D Printing

Ceramics are a type of material that is made of clay, glass, and metal oxides, which give it its unique properties. Ceramics are highly durable, heat-resistant, and have excellent electrical insulation properties. These properties make it an ideal choice for 3D printing, as it can be used to create parts with complex shapes and intricate details. The material is also relatively inexpensive compared to other materials used in 3D printing.

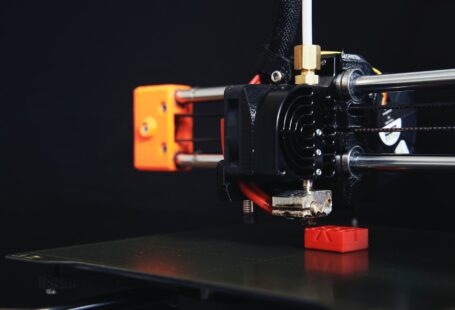

Advantages of Ceramics for 3D Printing

Ceramics offer several advantages when used in 3D printing. Firstly, the material is highly durable and can be used to create parts that are resistant to wear and tear. It is also heat-resistant, which makes it ideal for creating heat-resistant parts and components. Additionally, the material is highly conductive, making it ideal for creating parts with electrical components. Finally, the material is relatively inexpensive compared to other materials used in 3D printing, making it a cost-effective option.

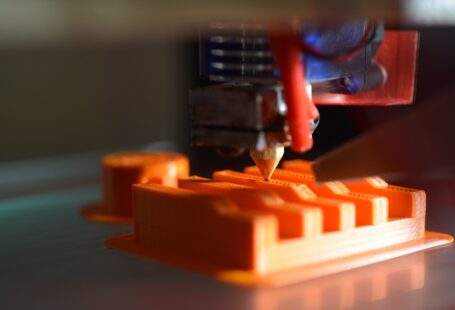

Applications of Ceramics for 3D Printing

Ceramics are being used in a variety of industries to create parts and components for 3D printing. One of the most common applications is in the production of medical implants and prosthetics. The material is highly durable and can be used to create parts that are resistant to wear and tear, which makes it ideal for long-term use in medical applications. Additionally, the material is highly conductive, making it ideal for creating medical implants and prosthetics with electrical components.

Another application of ceramics for 3D printing is in the automotive industry. The material is heat-resistant and can be used to create parts and components for engines, exhausts, and other high-temperature applications. Additionally, the material is highly conductive, making it ideal for creating electronic components for cars. Finally, the material is relatively inexpensive, making it a cost-effective option for creating parts for vehicles.

Conclusion

Ceramics are being used to redefine the capabilities of 3D printing. The material is highly durable, heat-resistant, and has excellent electrical insulation properties, making it an ideal choice for 3D printing. It is being used in a variety of industries to create parts and components for medical implants, prosthetics, and automotive applications. The material is relatively inexpensive compared to other materials used in 3D printing, making it a cost-effective option. As 3D printing technology continues to evolve, ceramics are likely to become an even more important part of the industry.