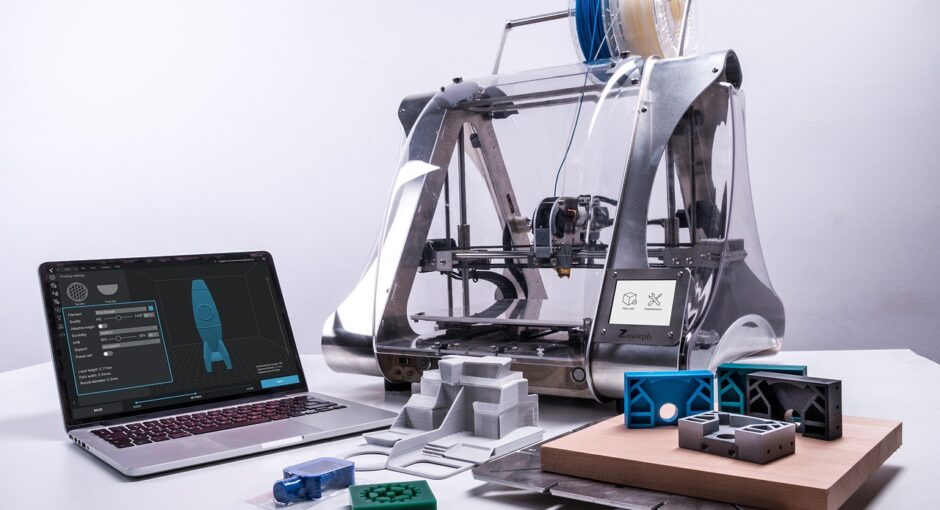

Aerospace 3D Printing is an exciting technology that has become increasingly popular for producing complex components and parts for aircraft. Its ability to create complex geometries quickly and cheaply has made it a valuable tool for many firms in the aerospace industry. But when it comes to 3D printing, different materials can produce very different results. Choosing the right material for your aerospace 3D printing project is essential for ensuring that the printed component is strong, durable, and meets all regulatory requirements.

Types of Aerospace 3D Printing Materials

When it comes to materials used for aerospace 3D printing, there are three main categories: thermoplastics, metal alloys, and composites. Each type has its own unique properties and advantages, and it’s important to understand the differences between them in order to select the best material for your project.

Thermoplastics

Thermoplastics are the most commonly used type of material for aerospace 3D printing. They are lightweight, strong, and easy to shape, making them well-suited for complex components. Commonly used thermoplastics include ABS, polycarbonate, nylon, and polypropylene.

Metal Alloys

Metal alloys are often used for aerospace 3D printing projects that require high strength and durability. Commonly used metal alloys include aluminum, stainless steel, titanium, and copper. These materials are strong, heat-resistant, and have a high melting point, which makes them ideal for components that must withstand extreme temperatures and pressures.

Composites

Composites are a combination of two or more materials, such as carbon fiber and metal alloys. They are often used for aerospace 3D printing projects that require a combination of strength and lightweight properties. Commonly used composites include carbon fiber reinforced plastic (CFRP) and glass fiber reinforced plastic (GFRP).

Choosing the Right Material for Your Project

When selecting a material for your aerospace 3D printing project, it’s important to consider the application and the desired properties of the final product. For example, if the component needs to be lightweight and strong, then a thermoplastic may be the best choice. On the other hand, if the component needs to be durable and heat-resistant, then a metal alloy may be the best option. Additionally, it’s important to consider the cost and availability of the material.

Conclusion

Choosing the right material for your aerospace 3D printing project is essential for ensuring that the finished product is strong, durable, and meets all regulatory requirements. Thermoplastics, metal alloys, and composites are all viable options, but it’s important to consider the application and the desired properties of the final product before selecting a material. By doing so, you can ensure that your component is produced to the highest standards.