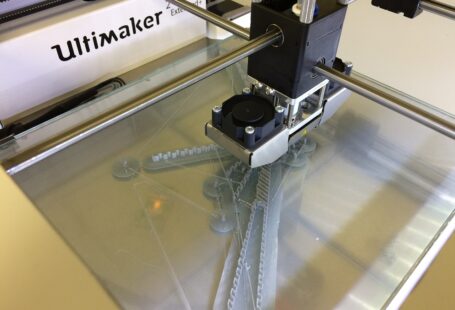

The 3D printing industry has seen tremendous growth in recent years due to the introduction of new technologies and materials. One of the newest materials to join the 3D printing world is glass, and it has opened up a range of possibilities for designers, engineers, and manufacturers. This article will discuss the advancements in glass 3D printing, from materials to applications.

Materials Used in Glass 3D Printing

Glass 3D printing relies on a range of different materials, including glass powder, silica sand, and various glass composites. Glass powder is a fine powder made up of silicate compounds, which can be used as a feedstock for 3D printing. Silica sand, on the other hand, is a naturally occurring material made up of silicon dioxide. It has been used in 3D printing for many years, but newer glass 3D printing technologies are now able to use it for more complex designs. Glass composites, such as those made with borosilicate glass, are also being used in 3D printing. These materials are strong and heat-resistant, making them well-suited for a range of applications.

Advantages of Glass 3D Printing

Glass 3D printing offers a number of advantages over traditional manufacturing techniques. The ability to produce complex geometries using glass 3D printing means that designers and engineers can create intricate parts and components that would not be possible with other manufacturing methods. The use of glass composites also allows for the production of components that are stronger and more durable than those made with traditional materials. In addition, glass 3D printing is faster and more cost-effective than other manufacturing techniques, making it a viable option for large-scale projects.

Applications of Glass 3D Printing

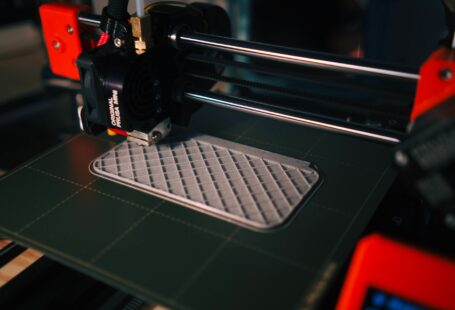

Glass 3D printing is being used in a variety of industries, including automotive, aerospace, medical, and consumer electronics. In the automotive industry, glass 3D printing is being used to produce complex components such as engine blocks and exhaust systems. In the aerospace industry, glass 3D printing is being used to produce complex parts and components for aircraft, satellites, and space exploration vehicles. In the medical field, glass 3D printing is being used to produce implants and prosthetics. And in the consumer electronics industry, glass 3D printing is being used to produce components for smartphones, tablets, and other devices.

Conclusion

Glass 3D printing is a rapidly advancing technology that is making it possible to produce complex components that were not possible with traditional manufacturing techniques. The use of glass composites and glass powders is allowing for the production of components that are stronger and more durable than those made with traditional materials. And the speed and cost-effectiveness of glass 3D printing is making it a viable option for large-scale projects. As the technology continues to evolve, we can expect to see more and more applications for glass 3D printing in a range of industries.