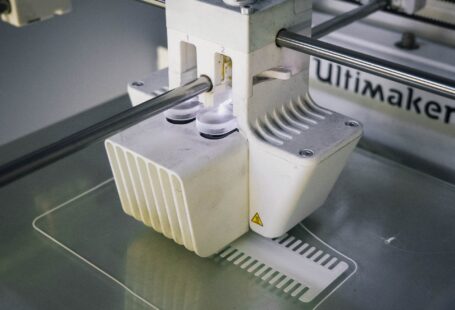

3D printing has become a popular technology across a range of industries and applications. One of the most popular materials used in 3D printing is high-impact polystyrene (HIPS), which is a lightweight, durable, and cost-effective material. In this article, we’ll take a look at the properties of HIPS and how it can be used in 3D printing.

What is High-Impact Polystyrene?

High-impact polystyrene, or HIPS, is a thermoplastic polymer that is widely used for its excellent chemical and mechanical properties. It is a relatively low-cost material that is easy to process and shape into a variety of products. It is also resistant to shock and impact, making it an ideal choice for applications where durability and strength are required.

Properties of HIPS

HIPS has a number of desirable properties that make it an ideal choice for 3D printing. It is lightweight, strong, and cost-effective. It is also resistant to shock and impact, making it an ideal choice for applications that require durability and strength.

The material has a low melting point, which makes it easy to process and shape into a variety of products. It is also highly resistant to chemicals, which makes it a great choice for applications that require resistance to solvents and oils.

How is HIPS Used in 3D Printing?

HIPS is widely used in 3D printing as a support material. It is used to provide support for intricate parts and features, such as bridges, overhangs, and complex geometries. The material is also used to create a smoother surface finish on the part or object being printed.

HIPS is also used as a filament in 3D printing. It is a cost-effective and lightweight material that is easy to process and shape into a variety of products. It is also resistant to shock and impact, making it an ideal choice for applications that require durability and strength.

Advantages of HIPS in 3D Printing

There are a number of advantages to using HIPS in 3D printing. The material is lightweight, strong, and cost-effective. It is also highly resistant to chemicals, making it a great choice for applications that require resistance to solvents and oils.

The material also has a low melting point, which makes it easy to process and shape into a variety of products. It is also highly resistant to shock and impact, making it an ideal choice for applications that require durability and strength.

Conclusion

High-impact polystyrene is an ideal choice for 3D printing, due to its excellent chemical and mechanical properties. It is lightweight, strong, and cost-effective, and is also resistant to shock and impact. It is also highly resistant to chemicals, making it a great choice for applications that require resistance to solvents and oils. As such, HIPS is a popular material for 3D printing and is used for a variety of applications, from intricate parts and features to smoother surface finishes.