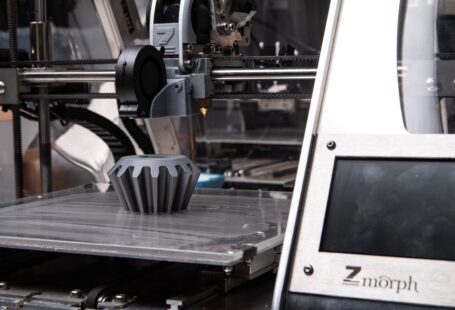

3D printing with bronze has become a popular manufacturing method due to its versatility and ability to create complex and intricate designs. While bronze is not as widely used as other metals, it offers some unique advantages for 3D printing. This comprehensive guide will provide an overview of the basics of 3D printing with bronze, including the materials used, the processes involved, and the benefits of using this method.

Materials Used

Bronze is an alloy composed of copper and tin. It is a strong, durable material that is highly resistant to corrosion and oxidation. The most common type of bronze used in 3D printing is a copper-tin alloy, although other alloys such as aluminum bronze and silicon bronze can also be used. The bronze filament used in 3D printing usually has a diameter of 1.75 mm or 2.85 mm.

Processes Involved

3D printing with bronze is a multi-step process that involves melting the bronze filament, forming a 3D structure, and then cooling the structure.

The first step is to melt the bronze filament. This is done by heating the filament to a temperature of about 900-1000 degrees Celsius. Once the filament is melted, it can be formed into a 3D structure by using a 3D printer. The 3D printer uses a computer-controlled nozzle to deposit the molten bronze in layers according to a 3D design file.

The next step is to cool the 3D structure. This is done by allowing the structure to cool slowly to room temperature. This ensures that the bronze is solidified and does not warp or deform due to rapid cooling. It also helps to avoid stress points in the structure due to thermal contraction.

Finally, the 3D structure can be post-processed to give it a desired finish. This can include polishing the surface, removing any imperfections, and applying a protective coating to the bronze.

Benefits of 3D Printing With Bronze

3D printing with bronze offers several advantages. First, it is a cost-effective manufacturing process. 3D printing eliminates the need for expensive tooling and allows for complex designs to be created quickly and easily. This can help to reduce the cost of production and lead to more efficient production processes.

Second, bronze is a strong and durable material that is highly resistant to corrosion and oxidation. This makes it ideal for use in applications where parts must be resistant to wear and tear.

Third, bronze has a low thermal expansion coefficient which makes it suitable for use in applications where parts must maintain their dimensions over a wide range of temperatures. This is especially beneficial in aerospace and automotive applications where parts must be able to withstand extreme temperatures.

Finally, bronze is a malleable material which makes it suitable for use in applications where parts must be able to flex and bend without breaking. This makes it ideal for use in applications such as robotics and medical implants.

Conclusion

3D printing with bronze offers a number of unique advantages for manufacturers. It is a cost-effective process, and the bronze material is strong and durable. It also has a low thermal expansion coefficient, making it suitable for use in applications where parts must maintain their dimensions over a wide range of temperatures. Finally, bronze is a malleable material which makes it ideal for use in applications where parts must be able to flex and bend without breaking.