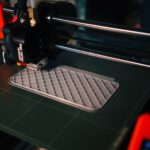

The advent of 3D printing technology has revolutionized the manufacturing process and given rise to numerous applications in various industries. One factor that plays an important role in the performance of 3D printing is the material’s density. This article will discuss the influence of material density on 3D printing and the implications it can have on the quality of the final product.

What is Material Density?

Material density is the measure of a material’s mass relative to its volume. It is expressed in units of grams per cubic centimeter (g/cm³). The density of a material is an important factor in 3D printing because it affects the way a material behaves when heated and cooled. Higher density materials tend to be stronger and more durable, and can withstand higher temperatures. Lower density materials are more pliable and can be more easily shaped.

How Does Material Density Affect 3D Printing?

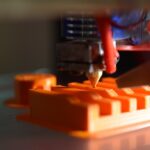

Material density affects 3D printing in several ways. Firstly, higher density materials require more energy to heat and cool, and thus take longer to print. This can lead to a slower printing process and can result in a poorer quality print. Secondly, material density also affects the strength of the finished product. Higher density materials are usually stronger and more durable, which can be beneficial for certain applications. On the other hand, lower density materials are often more pliable and can be more easily shaped, making them ideal for use in more intricate designs.

Types of Materials

When it comes to 3D printing, there are several types of materials that can be used. These include thermoplastic polymers, metals, ceramics, composites, and more. Each material has its own unique properties and characteristics, and these can vary greatly in terms of their densities. For example, thermoplastic polymers tend to have low densities while metals tend to have higher densities.

Implications of Density on Final Product

The density of a material can have a significant impact on the quality of the final product. Higher density materials tend to be stronger and more durable, which can be beneficial for certain applications. On the other hand, lower density materials are often more pliable and can be more easily shaped, making them ideal for use in more intricate designs.

In addition, the density of the material can also affect the cost of the 3D printing process. Higher density materials require more energy to heat and cool, which can lead to increased costs. Furthermore, higher density materials tend to be more expensive than lower density materials, which can also increase the cost of the 3D printing process.

Conclusion

In conclusion, material density is an important factor that can have a significant impact on the performance of 3D printing. Higher density materials tend to be stronger and more durable, while lower density materials are often more pliable and can be more easily shaped. The density of the material can also affect the cost of the 3D printing process. Understanding the implications of material density on 3D printing can help manufacturers and designers make more informed decisions when selecting materials for their projects.