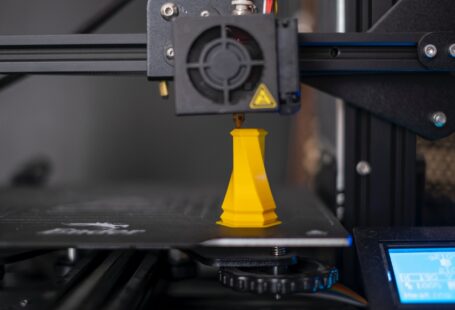

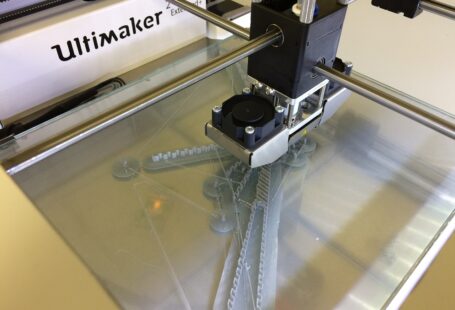

When it comes to 3D printing, the cost and quality of the material used plays a major role in the outcome of the final product. Depending on the type of product that you are looking to create, you may need to consider the cost and the quality of the material before making a decision. In this article, we will look at the varying types of 3D printing materials available, their pros and cons, and how to choose the right one for your specific project.

Types of 3D Printing Materials

When it comes to 3D printing materials there are a variety of options to choose from. Each type of material offers its own unique benefits and drawbacks. The most popular 3D printing materials are:

- PLA (Polylactic Acid)

- ABS (Acrylonitrile Butadiene Styrene)

- Nylon

- Polycarbonate

- Metal

Each type of material has its own unique properties and advantages. PLA is the most commonly used 3D printing material due to its affordability and ease of use. It is also biodegradable, making it an environmentally friendly option. ABS is a slightly more expensive material but is known for its durability and strength. Nylon is another popular choice due to its flexibility and heat-resistance. Polycarbonate is an expensive but strong material that is often used for industrial applications. Finally, metal is an ideal choice for creating complex designs due to its strength and durability.

Cost vs Quality

When it comes to choosing the right 3D printing material, cost and quality are two of the most important factors to consider. Generally speaking, the cost of the material will increase as the quality does. This means that if you are looking to create a higher quality product, you will likely need to invest in a more expensive material. However, it is important to remember that cost is not always an accurate reflection of quality. For example, the cost of ABS is often higher than PLA, but PLA is known for being an easier material to work with.

Finding the Right Balance

Finding the right balance between cost and quality is key when selecting the right 3D printing material for your project. Generally speaking, it is best to opt for a material that offers the best quality for the least amount of money. In addition, you should also consider the specific needs of your project. For example, if you are looking to create a product that needs to be durable and heat resistant, nylon or polycarbonate may be the best option. On the other hand, if you are looking to create a product that requires intricate detail, metal may be the way to go.

Conclusion

At the end of the day, choosing the right 3D printing material for your project comes down to finding the right balance between cost and quality. Each type of material has its own unique benefits and drawbacks, so it is important to consider the specific needs of your project before making a decision. Once you have a better understanding of the types of materials available and the cost and quality associated with each one, you will be able to make an informed decision and create a product that meets your needs.