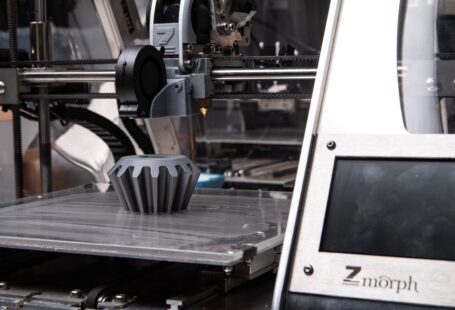

The 3D printing industry is rapidly evolving, and one of the most exciting developments is the use of multi-material 3D printing. This innovative technology allows for the creation of objects with multiple materials, such as plastics, metals, and composites, all in one build. This has opened up a world of possibilities for manufacturers, designers, and engineers, and it is revolutionizing the way products are designed and manufactured.

The Benefits of Multi-Material 3D Printing

Multi-material 3D printing has a number of advantages over traditional manufacturing methods. It allows for the creation of complex objects that would otherwise be difficult or impossible to produce using traditional methods. For example, it can be used to create parts with intricate geometries, or parts with multiple materials in a single build. It also allows for the creation of objects with different properties, such as stiffness, toughness, or flexibility, all in one print.

In addition, multi-material 3D printing is much faster and more cost-effective than traditional manufacturing methods. It eliminates the need for tooling, and it can produce parts in a fraction of the time and cost that it would take to produce them using traditional methods. This makes it an attractive option for manufacturers, especially those looking to reduce costs and increase efficiency.

The Potential Applications of Multi-Material 3D Printing

Multi-material 3D printing has a wide range of potential applications. It can be used for the production of complex objects, such as medical devices, aerospace components, and consumer electronics. It can also be used for the production of custom parts, such as orthopedic implants and prosthetics. It can be used for rapid prototyping, allowing engineers to quickly test out designs and concepts.

In addition, multi-material 3D printing can be used for the production of objects with multiple functions, such as an object that can both heat up and cool down. This opens up a world of possibilities for product designers and engineers, as they can create products with multiple functions in a single build.

The Challenges of Multi-Material 3D Printing

While multi-material 3D printing offers a number of advantages, it also comes with its own set of challenges. One of the biggest challenges is the complexity of the printing process. Printing multiple materials in one build can be difficult, and it requires a high level of precision and accuracy. In addition, the materials that can be used in a multi-material 3D print are often limited, and some materials may not be compatible with the 3D printer.

The Future of Multi-Material 3D Printing

Multi-material 3D printing is still in its early stages, but it is quickly becoming an essential tool for manufacturers, designers, and engineers. As the technology continues to evolve, it is likely that we will see an increase in the variety of materials that can be used in a multi-material 3D print. This will open up a world of possibilities for product designers and engineers, allowing them to create objects with multiple functions in a single build.

Overall, multi-material 3D printing is an exciting and rapidly evolving technology that is revolutionizing the way products are designed and manufactured. It offers a number of advantages over traditional manufacturing methods, and it is quickly becoming an essential tool for manufacturers, designers, and engineers. As the technology continues to improve, we can expect to see an increase in the variety and complexity of objects that can be produced using multi-material 3D printing.