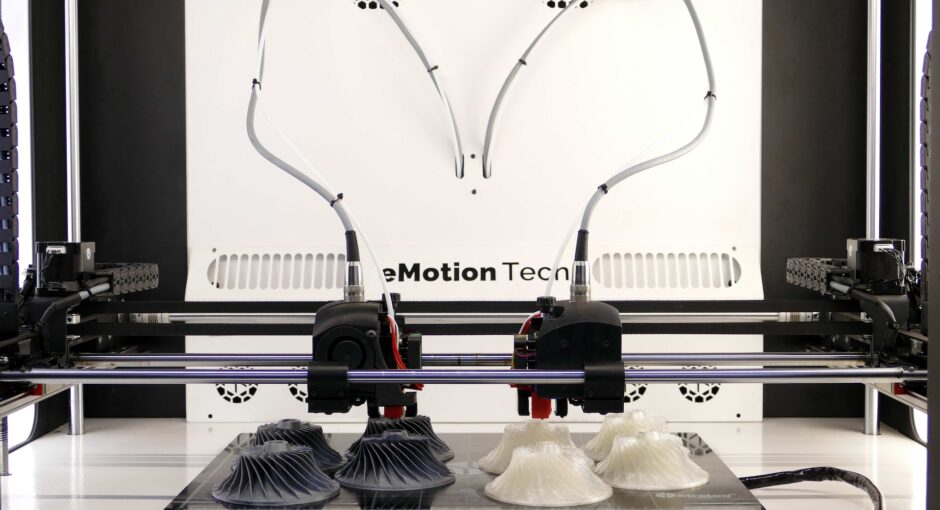

The world of 3D printing is constantly evolving and, as such, the materials used to create 3D printed objects are expanding. This includes the use of rubber materials, which have a number of applications and implications for 3D printing.

Uses of Rubber in 3D Printing

Rubber is a versatile material that can be used in 3D printing for a variety of applications. It can be used to create flexible parts for a variety of products, from medical devices to automotive components. It can also be used to produce complex shapes and structures, such as custom gaskets and seals. In addition, rubber can be used to create parts for shock absorption or to reduce vibration.

Advantages of Rubber for 3D Printing

Using rubber materials for 3D printing has a number of advantages. Rubber is a durable material that is resistant to wear and tear and can withstand extreme temperatures. It is also flexible, allowing for the production of complex shapes and structures. The material is also lightweight and can be used to produce parts with a high degree of detail.

Implications of 3D Printing with Rubber

The use of rubber in 3D printing has a number of implications. 3D printing with rubber materials can reduce production costs, as the material is less expensive than other materials such as metal or plastic. It can also reduce the need for manual labor, as the parts can be produced quickly and efficiently. Furthermore, the use of rubber in 3D printing can improve product quality, as the material is durable and resistant to wear and tear.

The Future of 3D Printing with Rubber

The use of rubber in 3D printing is likely to become more widespread as the technology continues to evolve. The use of rubber materials will allow for more complex shapes and structures to be produced, as well as the production of parts for a range of applications. As the technology improves, the cost of production is likely to decrease, making 3D printing with rubber a more attractive option for businesses.

In conclusion, the use of rubber materials in 3D printing has a number of advantages and implications. Rubber is a versatile material that is durable, flexible and can be used to produce complex shapes and structures. 3D printing with rubber can reduce production costs and improve product quality, making it an attractive option for businesses. As the technology continues to evolve, the use of rubber in 3D printing is likely to become more widespread.