The world of 3D printing has come a long way since its inception. From the humble beginnings of FDM and SLA technology, to the more advanced technologies such as SLS and DMLS, 3D printing has become a staple of the industry. One of the newer technologies to emerge is wax 3D printing. Wax 3D printing has become increasingly popular due to its ability to create complex, intricate parts with a high level of detail. In this article, we will take a closer look at wax 3D printing and the benefits it provides.

What is Wax 3D Printing?

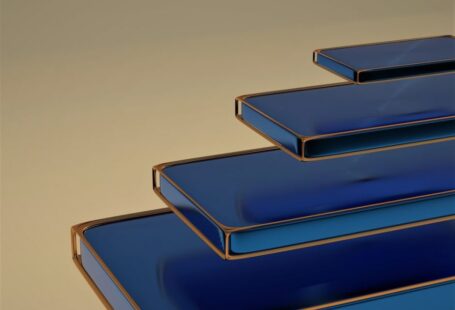

Wax 3D printing, also known as lost wax casting, is a process that utilizes a 3D printing method to create a wax model of a desired object. This model is then used as a master pattern for casting metal parts. This process has been around for thousands of years and is still in use today. The wax model is created by depositing successive layers of wax onto a build platform. The wax is then heated to create a solid model.

Benefits

Wax 3D printing offers a number of benefits over traditional manufacturing methods. One of the main benefits is its ability to create intricate parts with a high level of detail. Wax 3D printing can produce parts with complex geometries and features that would otherwise be impossible to produce with traditional methods. The wax model can also be used to create molds for casting metal parts. This allows for the creation of parts that are both strong and lightweight.

Another benefit of wax 3D printing is its cost-effectiveness. Wax 3D printing is much cheaper than traditional manufacturing methods, as it does not require expensive tooling or machinery. This makes it a great option for small businesses or individuals who need to produce parts in low volumes.

Applications

Wax 3D printing is used in a variety of industries, from jewelry and dental to aerospace and automotive. In the jewelry industry, wax 3D printing is used to create intricate pieces of jewelry with a high level of detail. In the dental industry, wax 3D printing can be used to produce dentures and prosthetics with a high level of accuracy. In the aerospace and automotive industries, wax 3D printing is used to create parts with complex geometries and features.

Conclusion

Wax 3D printing is a relatively new technology that has the potential to revolutionize the way we manufacture parts. It offers a number of benefits, such as its ability to create intricate parts with a high level of detail, its cost-effectiveness, and its application in a variety of industries. If you’re looking to produce parts with complex geometries and features, wax 3D printing may be the right solution for you.