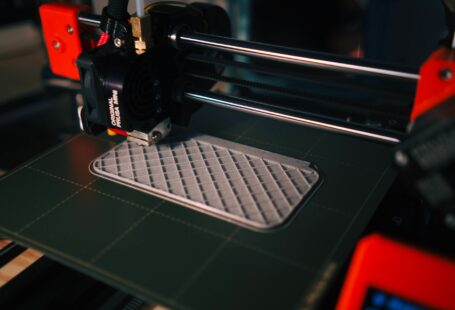

The recent rise in 3D printing technology has opened up a range of possibilities for engineers and designers. One of the most interesting areas of exploration is the development of conductive materials for 3D printing. This technology has the potential to revolutionize the way we create and assemble electronics and could have far-reaching applications in the industrial, medical, and consumer markets.

What are Conductive Materials?

Conductive materials are those that are able to conduct electricity. They can be metallic or non-metallic, but they must possess certain electrical properties in order to work. Common conductive materials include metals like copper or aluminum, as well as carbon, graphite, and some plastics.

The Benefits of Conductive Materials for 3D Printing

Using conductive materials for 3D printing can provide a number of advantages. For example, they can be used to create complex and intricate electronic components that would be difficult or impossible to produce using traditional methods. They also allow for components to be produced in a single step, eliminating the need for multiple fabrication processes. This can reduce costs and lead times, making 3D printing a more attractive option for large-scale production.

Additionally, conductive materials allow for greater design flexibility. Because they are able to conduct electricity, they can be used to create circuits and sensors that can be incorporated into a 3D printed object. This opens up a range of possibilities for creating interactive and intelligent objects.

Challenges of Developing Conductive Materials for 3D Printing

Developing conductive materials for 3D printing is not without its challenges. One of the main issues is the need for the material to be both conductive and printable. This means that the material must have the necessary electrical properties, as well as the ability to be extruded from a 3D printer without clogging the nozzle.

Another challenge is that conductive materials often require higher temperatures than other 3D printing materials. This can lead to warping and other issues with the printed part. Additionally, conductive materials can be difficult to post-process, as the material must be treated in a special way in order to ensure that it retains its conductivity.

Emerging Solutions

Despite the challenges, there are a number of emerging solutions that are helping to make conductive materials more printable. For example, research is being done into the development of new conductive materials that are able to be extruded at lower temperatures. Additionally, there are a number of 3D printing techniques that are being used to produce conductive structures, such as laser sintering and inkjet printing.

In addition to the materials themselves, there are a number of other advances that are helping to make 3D printing of conductive materials more viable. For example, there are special 3D printer nozzles that are designed specifically for extruding conductive materials. Additionally, there are special post-processing techniques that are being developed to help preserve the conductivity of 3D printed parts.

Conclusion

The development of conductive materials for 3D printing is an exciting and rapidly evolving field. With advances in materials and 3D printing technology, the possibilities for creating complex and interactive 3D printed objects are becoming increasingly viable. As such, this technology has the potential to revolutionize the way we create and assemble electronics, with far-reaching implications for industry, medicine, and consumer products.