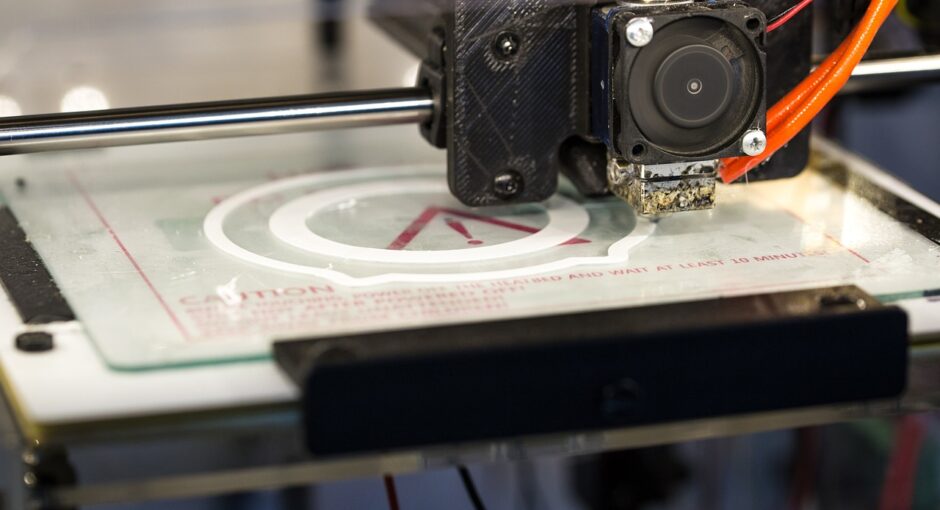

The use of 3D printing in industrial settings has grown exponentially in the past few years, and with it, the need for higher-performing materials. Advanced materials, such as metals and composites, are now being developed specifically for use in industrial 3D printing applications. These materials provide superior performance, strength, and durability, while opening up new possibilities for 3D printing applications.

The Benefits of Advanced Materials

Advanced materials have the potential to revolutionize 3D printing in industrial settings. They offer a number of advantages over traditional materials, including:

- Greater strength and durability

- Improved mechanical properties

- Reduced weight and complexity

- Increased part performance

- Improved aesthetics and design flexibility

These advantages allow for 3D printed parts to be used in a wide range of applications, from aerospace to automotive. By using advanced materials, manufacturers can create parts that are more reliable, lightweight, and cost-effective.

Types of Advanced Materials

There are a variety of advanced materials available for industrial 3D printing. These include:

- Metals: Metals such as stainless steel, aluminum, and titanium alloys are the most commonly used materials in industrial 3D printing. They provide superior strength and durability, and can be used to create intricate and complex parts.

- Composites: Composite materials, such as carbon fiber reinforced polymers and continuous fiber reinforced composites, offer the advantages of both metals and plastics. They can be used to create lightweight, strong, and highly durable parts.

- Ceramics: Ceramics are becoming increasingly popular for industrial 3D printing applications. They are strong, lightweight, and resistant to high temperatures and corrosion.

- Polymers: Polymers are the most commonly used materials in 3D printing. They are versatile, cost-effective, and can be used to create a variety of different parts.

Applications of Advanced Materials

Advanced materials can be used to create parts for a wide range of industries. This includes aerospace, automotive, medical, and consumer products. In aerospace, for example, advanced materials can be used to create lightweight and durable parts for aircraft. In the automotive industry, advanced materials can be used to create complex and lightweight parts that are more efficient and reliable. In the medical industry, advanced materials can be used to create custom implants and prosthetics that are tailored to the individual patient. In consumer products, advanced materials can be used to create a variety of products, from phone cases to jewelry.

Conclusion

Advanced materials have the potential to revolutionize 3D printing in industrial settings. They offer superior performance, strength, and durability, while opening up new possibilities for 3D printing applications. By taking advantage of advanced materials, manufacturers can create parts that are lightweight, strong, and cost-effective. This allows for 3D printed parts to be used in a wide range of industries, from aerospace to automotive.