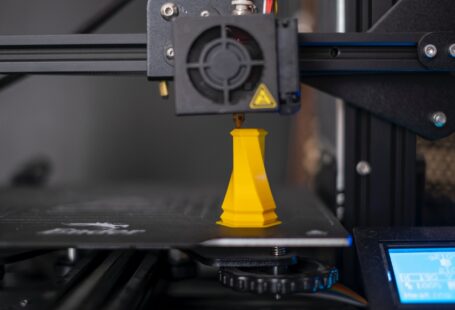

The world of 3D printing is an ever-evolving domain, with new materials being developed and tested all the time. Choosing the right 3D printing material for your project can be a daunting task, but it doesn’t have to be. In this ultimate guide to 3D printing materials, we’ll explore the different types of materials available for 3D printing and provide you with all the information you need to make an informed decision.

Types of 3D Printing Materials

3D printing materials can be broadly divided into two categories: thermoplastics and composite materials. Thermoplastics are polymers that become soft when heated and harden when cooled. They are the most commonly used 3D printing materials and are available in a variety of colors and textures. Composite materials are mixtures of thermoplastics and other substances, such as metal, ceramic, or glass. They offer more design flexibility than thermoplastics and can be used to create complex shapes and intricate details.

Common Thermoplastics

- ABS (Acrylonitrile Butadiene Styrene): A durable, lightweight, and heat-resistant thermoplastic commonly used in the automotive and electronics industries. It’s great for prototyping and producing parts with intricate details.

- PLA (Polylactic Acid): A biodegradable thermoplastic made from renewable resources, such as cornstarch or sugar cane. It’s easy to use and has a low melting point. It’s often used for medical and educational purposes.

- PET (Polyethylene Terephthalate): A durable and lightweight thermoplastic used to produce food and beverage containers. It’s also used in 3D printing, as it is resistant to many chemicals and can be used for intricate designs.

- Nylon: A strong, flexible, and lightweight thermoplastic used in a variety of industries, such as automotive, electronics, and medical. It’s popular for 3D printing because it can be used to create complex shapes and intricate details.

- TPU (Thermoplastic Polyurethane): A flexible and elastic thermoplastic used in a variety of applications, including automotive and medical. It’s often used for prototyping and producing parts with intricate details.

Common Composite Materials

- Metal: Metal filaments are made from powdered metals, such as copper, bronze, and stainless steel. They are often used for creating strong and durable parts with intricate details.

- Ceramic: Ceramic filaments are made from ceramic powder. They are often used for creating parts with high heat resistance.

- Wood: Wood filaments are made from wood fibers and other natural materials, such as bamboo and cork. They are often used for creating parts with a natural wood-like finish.

- Glass: Glass filaments are made from glass powder. They are often used for creating parts with a glossy, glass-like finish.

- Carbon Fiber: Carbon fiber filaments are made from carbon fiber strands and are often used for creating strong and lightweight parts.

Choosing the Right Material

When choosing the right 3D printing material for your project, it’s important to consider the properties of the material and how it will be used. Factors such as strength, flexibility, heat resistance, and durability should all be taken into account.

If you’re looking for a material with a high strength-to-weight ratio, then thermoplastics like ABS or nylon would be a good choice. If you’re looking for a material that is flexible and elastic, then TPU or a composite material like carbon fiber would be a good choice. If you’re looking for a material with a glossy finish, then a composite material like glass or ceramic would be a good choice.

Conclusion

3D printing materials come in a variety of types and can be used to create a wide range of products. Choosing the right 3D printing material for your project can be a daunting task, but it doesn’t have to be. By understanding the different types of materials available and considering the properties of the material and how it will be used, you can make an informed decision about which material is right for your project.