The future of industrial manufacturing is set to be transformed by the implementation of composite materials in 3D printing. This innovative approach to fabrication has the potential to revolutionize the industry, enabling the production of components with superior strength, durability, and cost-effectiveness.

The Benefits of 3D Printing

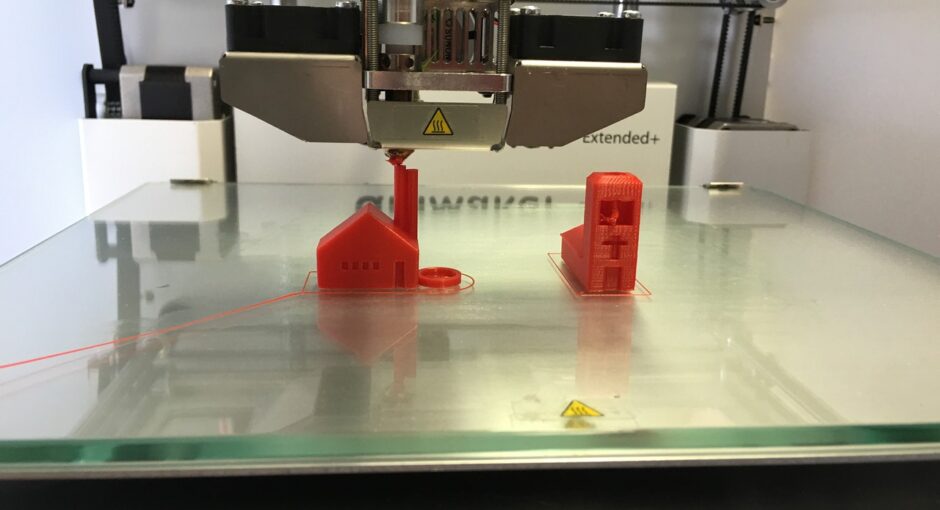

3D printing has become increasingly popular in recent years, thanks to its numerous advantages. It is a cost-effective, quick, and accurate way of producing complex components, and it has the potential to drastically reduce the cost and time needed to manufacture products. Additionally, 3D printing allows for the fabrication of components with unique designs, shapes, and sizes, which cannot be produced with traditional manufacturing techniques.

Composite Materials in 3D Printing

The use of composite materials in 3D printing has the potential to further revolutionize the industrial manufacturing process. These materials are a combination of two or more materials that have been specifically designed for a particular application. Composite materials have superior strength and durability, as well as increased flexibility and cost-effectiveness. They can also be tailored to meet specific requirements, such as weight, strength, and flexibility.

In the context of 3D printing, composite materials can be used to create components with superior strength and durability. This is because the combination of materials can create a stronger bond than is possible with traditional manufacturing techniques. Additionally, composite materials allow for the fabrication of components with unique shapes and sizes, which cannot be produced with traditional manufacturing techniques.

The Future of Industrial Manufacturing

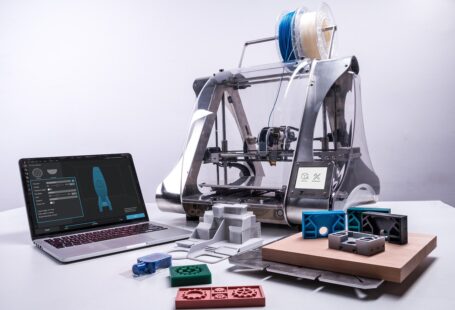

The use of composite materials in 3D printing has the potential to revolutionize industrial manufacturing. It is an efficient, cost-effective, and accurate way of producing components with superior strength and durability. Additionally, it allows for the fabrication of components with unique shapes and sizes, which cannot be produced with traditional manufacturing techniques.

The implementation of composite materials in 3D printing is set to have a huge impact on the future of industrial manufacturing. It will enable the production of components with superior strength, durability, and cost-effectiveness, and it will drastically reduce the cost and time needed to manufacture products. It is clear that this innovative approach to fabrication has the potential to revolutionize the industry, and it is set to shape the future of industrial manufacturing for years to come.